Startup of the Week – GreenJams

| 5 minutes read

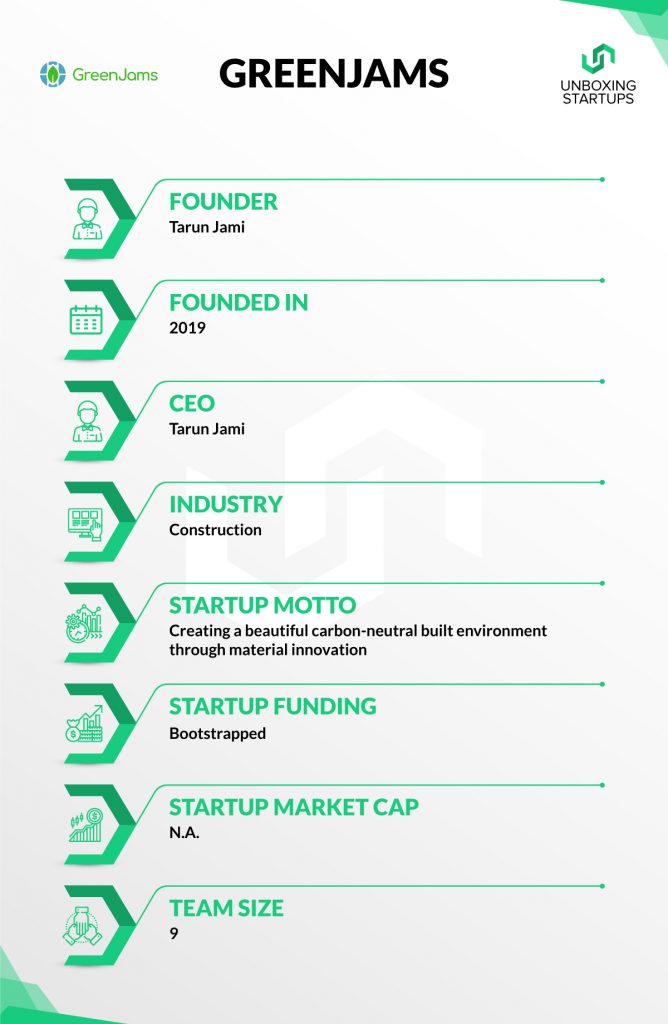

Founded in – 2019

Industry – Construction

Founder – Tarun Jami

CEO – Tarun Jami

Startup Motto – Creating a beautiful carbon-neutral built environment through material innovation

Startup Funding – Bootstrapped

Startup Market Cap – NA

Team Size – 9

Below is the transcript of our interview with GreenJams

Could you please tell us about GreenJams to our readers and entrepreneurs, what it is all about?

GreenJams is an award-winning cleantech startup pioneering carbon-negative building materials using crop residues and industrial by-products. The problems we solve are:

- 45% of global carbon emissions come from the built environment on account of space conditioning of buildings and manufacture of building materials

- About 100 million tonnes of crop residues are burnt annually in India, costing the country almost $30.76 Billion due to loss of productivity and impact on public health.

What is AGROCRETE, and could you please tell us what procedures you follow while making?

Agrocrete® is a carbon-negative building material made using crop residues like paddy straw, bagasse, cotton stalk, and others, which usually are burned, and an innovative new binder made using industrial by-products such as ashes, slags, and sludges from the steel, paper, and power plants, called BINDR™. It helps reduce the cost of construction by almost 50% and improves the building energy efficiency by 25%. We use a patent-pending zero-emissions manufacturing process based on advanced alkali-activation chemical technology. It’s a simple and scalable process and begins with collecting the crop residues, chopping them into small pieces, and treating them with hot water. Further, the crop residues are mixed with BINDR™ in a pan mixer. The resultant homogenous mass is transferred into a hydraulic block-making machine and compacted into dense blocks. The blocks are cured for 7 days and are then shipped out to be built with.

How do you get an idea of creating a carbon-neutral built environment through material innovation?

Late during my undergrad days, studying civil engineering, I had come across what climate change is and the impact that construction has on it. Since then, I got conscious of my role in the future destruction that construction would cause. Ever since I had developed this conviction, I was looking for technologies and materials that would help make construction less harmful to the environment. Towards the end of my engineering degree, I had stumbled upon a building material called hempcrete. It was carbon-negative and made of hemp, and it felt like I had discovered Wonderland. I suddenly realized that with hempcrete, we could make construction better for the planet. Can you imagine that? Construction could help reverse climate change. That epiphany set me on a journey that took me this far.

Do you manufacture the materials? Or any third-party company manufacture for you?

We have our own manufacturing capacities at the moment. However, we shall be scaling up through a franchise manufacturing model. We shall license the technology to individual rural entrepreneurs or other groups and organizations with access to the crop residues. They shall invest in the manufacturing equipment and source the raw materials locally. We provide technical support, marketing support, and BINDR™. The franchisee shall produce the blocks under the brand name of Agrocrete® and sell them to the market. BINDR™ shall be manufactured in-house by GreenJams.

From which state do you receive the maximum demand for carbon-neutral materials?

Agrocrete® is a carbon-negative building material, while our BINDR™ has a small carbon footprint. We’ve received inquiries from across the length and breadth of the country. But, most inquiries came from Maharashtra, Karnataka, Tamil Nadu, Andhra Pradesh, and Delhi-NCR.

On one of the websites, we read that you also solve crop residue burning, so our readers want to know how you do that?

The crop residues are procured from the farmers at a cost and mixed with BINDR™ to produce Agrocrete®. We compensate the farmers for their efforts to collect the crop residues and incentivize them by creating an additional source of income. The farmers also recognize the health hazards of burning the residues and are willing to collect them and sell them.

What are the challenges you faced during the initial days? And how did you push through?

There were so many. The biggest hurdles were technical and financial. While we were able to solve the financial hurdles, the technical ones were more difficult to overcome. I spent five years studying hempcrete academically to equip myself with the technical skills required to create Agrocrete®. In 2017 I had started my Ph.D. at CSIR-Central Building Research Institute (CSIR-CBRI), Roorkee.

What is your vision and mission behind this company? And where do you want to reach? Any future plans?

Our vision is to create a beautiful carbon-neutral built environment by creating products and services that help our customers lead a carbon-neutral lifestyle. We are confident that climate startups can also become unicorns and decacorns. While we are currently focused on bricks and blocks, we have our sights set on carbon-negative pre-engineered buildings and various other carbon-negative construction products and technologies that are climate positive and create a lot of economic value. We are looking at entering international markets in the next 2-3 years.

What have you failed at? And how do you recover from that phase? Because being an entrepreneur is not easy, it’s like walking on the stone each day. So what boosts your mind when you face failure?

Sometimes, entrepreneurs need to be toxic optimists. Failure is something that we face daily. Over the past seven years, I have failed thousands of times during product development. I had created at least 100 variations of Agrocrete® before achieving economic and technical feasibility. A few 100 failures later, I was able to improve its durability. A lot of failures later, I was able to surpass conventional materials in terms of technical properties. Failures are milestones, and you learn something new from each one of them. When you have a goal and a single-minded focus on achieving it, failures don’t matter. The big picture will always take you there.

In which cities you’re currently serving? Any further expansion plans?

We are currently supplying Agrocrete® blocks and BINDR™ to multiple residential projects in Punjab, Haryana, Uttarakhand, Delhi-NCR, and Uttar Pradesh. We are also setting up a new 2000 blocks per day manufacturing facility in Visakhapatnam, Andhra Pradesh. We have received an overwhelming number of inquiries since 13th July 2021 from Karnataka, Maharashtra, and Telangana. We are looking for franchising partners who could set up the Agrocrete® blocks manufacturing facilities in these markets.

Any secret formula to young entrepreneurs?

You might fail 1000 times before you succeed once, and that’s where history is created. During this journey, when you face failure, it is essential to grieve it, take a break and then come back renewed to examine what went wrong and improve on it. Also, be self-aware. Watch your thoughts, emotions, and actions. Every move you make matters. Last, of all, don’t take yourself too seriously and have as much fun as you can along the way.

Could you describe yourself in one word?

Skeptical optimist.

Before we conclude the interview, anything you want to say to the Unboxing Startups team?

Thank you so much for doing this and bringing out stories out in the open. Not everyone is meant to be an entrepreneur, and that’s okay. However, please do get this message out: everyone in this world is human capital. You may choose to startup or find a job. But whatever you do, please be mindful of the mission you’ll partake in. If you join a company that creates many carbon emissions, you will be responsible for future climate crises. When talented people choose not to work for polluting companies, you force a change for good.

Born in the family of entrepreneurs and have inherited the same. Started building applications in order to pay for my tuition. Later founded a tech company, marketing agency, and media outlets.